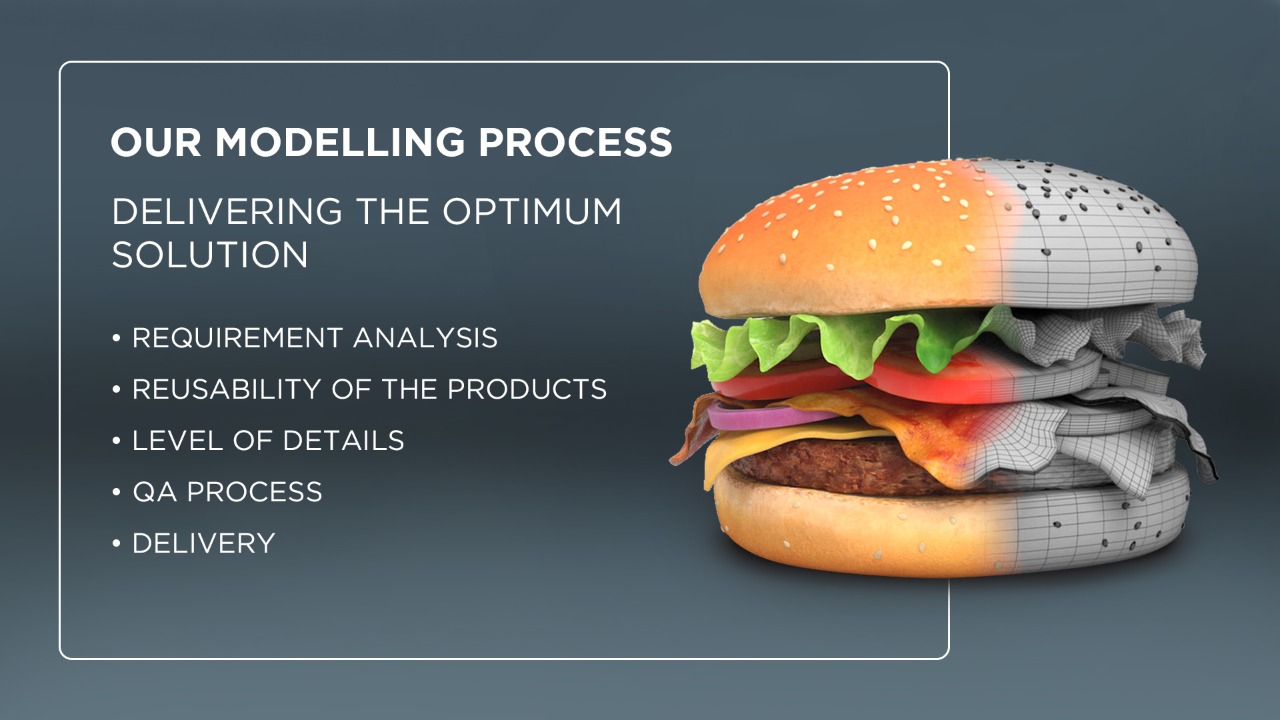

Emerging technologies are empowering and enabling the eCommerce industry to widen its horizons and thrive recklessly. We, at SuperDNA 3D lab, aim to revolutionize the e-commerce market through visual interaction and create in-store experiences for online buyers, leveraging digital avenues. To achieve that we have set up standard processes and methods which enable us to deliver the optimum solution to our customers. Here’s what goes behind our modeling process:

- Analyze RequirementWe have expertise in creating models as per LODs

As we commence our work for a customer, the first thing we do is understand the customer’s guidelines like the kind of software to be used for creating content and the environment required for product development. We then look at their business objective – what they are trying to achieve with 3D technologies and how they plan to leverage it to grow their business.

- Use AI to Find Reusability of Models

When the requirement of modeling is determined, we have it run through our in-built artificial intelligence system that helps in finding any usability of previously created models. This saves a lot of time, as we can reuse the elements from our library of pre-created models.

- Determine the Kind of Models

SuperDNA 3D Lab operates within the scope of three major levels of detail namely LOD 1, LOD 2 and LOD 3. LOD 1 is leveraged when we are dealing with 3D models of hard-surfaced objects. To lower the overall polygon count of such models, details such as bolts and screws can be excluded. This also serves as a 20-20 CAD symbol. LOD 2 is utilized for toning down the poly count of fabrics, AR/VR visuals and game imagery. And last but not least, LOD 3 is used when high-resolution, photorealistic room scenes are in consideration

- Perform 3D Modeling

At SuperDNA 3D lab, we create high and low polygon models suited for all business needs. We make 3D geometry objects which is the best way to present and understand any object from various angles. Our team of 3D specialists makes every effort to make the model photo realistic and reusable.

- QA Process

Our QA team checks into layers and dimensions and verifies modeling standards, such as scale, thickness, dimensions, etc. It is a standard quality assurance process that our QA team follows after modeling every product. Products further go to texturing team for performing various works like color, texture, bumps, etc. All the modeling aspects are meticulously examined and verified and if any scope of improvements is found, they are sent back to the modeling team for rework. A similar process is followed after the texturing as well.

- Render and Deliver in Various Formats:

3D models can be delivered in various formats like .3ds, .blend, .dae, .fbx, .obj. Generally, it depends on the 3D application which is going to make use of 3D models. For example, AR applications support the .dae format and CGI applications generally support the .3ds format. Rendering of each model from multiple camera angles like the front, back, and top perspective and close-ups are provided in the output.

SuperDNA 3D lab Quality Checklist:

- Verification of details given to the team and monitoring mechanism validates if the team can perform as per the set standards in the operation and delivery

- QA team checks the methods, approach, and quality of output

- QA team checks into layers and dimensions and verifies modeling standards, such as scale, thickness, dimensions, etc.

- If the QA team finds any error in the model, it is sent back to the modeling team for modification

- The process is observed in detail during the design and operations phase and is documented for future reference and staff training.

Challenges in 3D modeling:

- Uncontrolled Use of Polygons:

It is crucial to make use of 3D modeling software components efficiently. The polygon number should be kept to a minimum while building characters and objects. If it is not, then a modeler might get confused with numerous polygons through their project which usually leads to the formation of hundreds of polygons.

- Mesh:

One must create the right mesh design or spacing between the vertices to design the final composition. Representation can go wrong if the resolution is either too tight or spaced out. Clearly defined points offer better use of the shape whereas unimaginative defined one leads to poorly defined mesh. Therefore, it’s necessary to set the perfect spacing between various vertices and thereby improve the overall resolution.

- Shading:

First, you need to design shapes through polygon grouping and then make them appear live and solid objects, which can be achieved by shading. It is difficult for beginners to manipulate the different types of changes that occur whenever the same object passes through different lighting environments.

How SuperDNA 3D lab Team is Differentiated

We aim to provide the best services to our customers, from the initial phase to the final delivery of the product. We have a defined quality management process, where we consistently work on our quality assurance system, delivery process, methodologies, and customer services which can fulfill international standards. We are dominant in creating assets across the globe. We are a firm committed to the best and qualitative work approach, whether it is a high poly or a low poly model. Our specialized 3D team leaves no stone unturned to deliver the highest quality products that meet global standards.